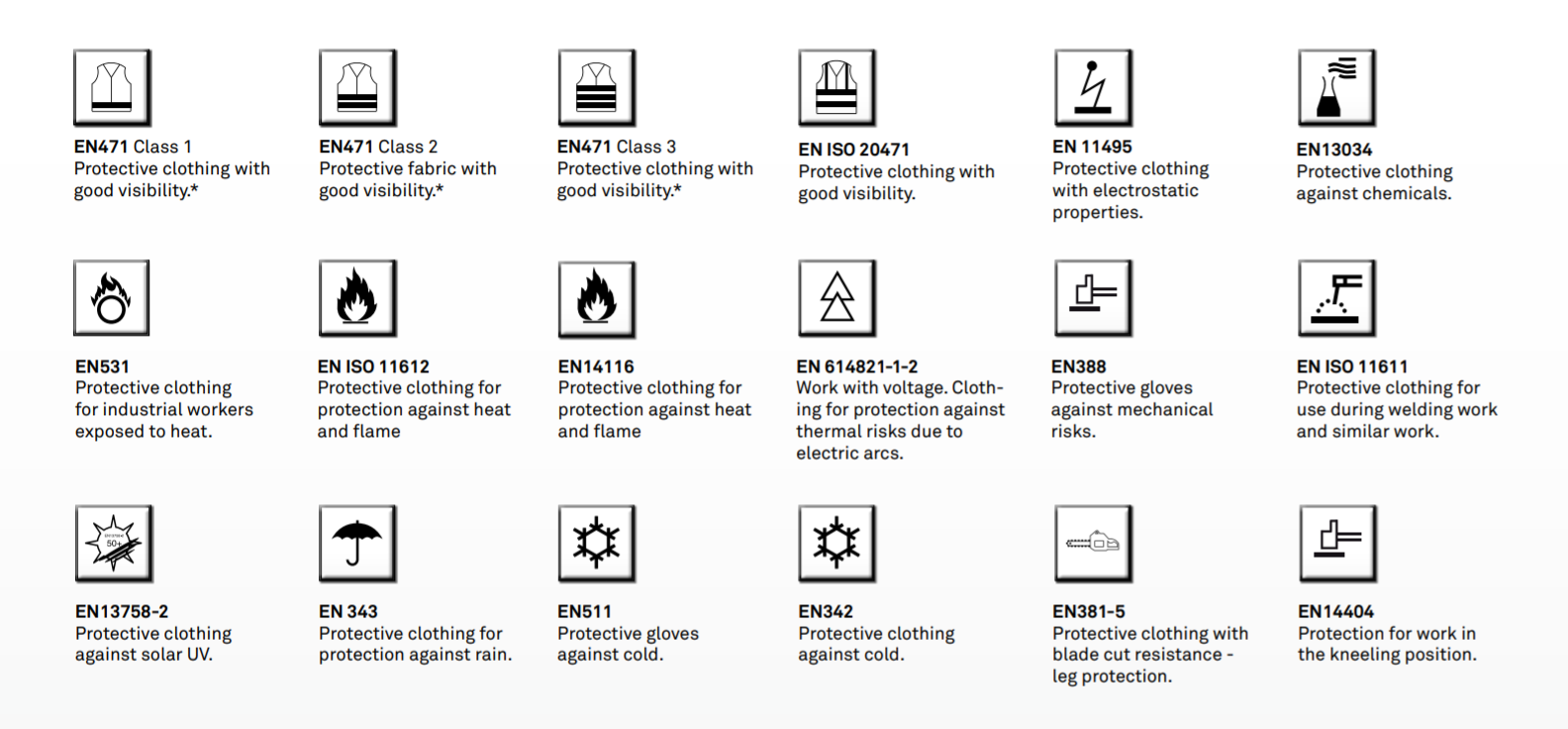

LCC Clothing Ireland makes workwear which falls under the definition of personal protective equipment (PPE), and is therefore marked in accordance with the CE marking regulations (EN standards). Such workwear is intended to protect against accidents or injuries when working under conditions involving cold, heat, flame, rain and reduced visibility.

LCC Clothing Ireland makes workwear which falls under the definition of personal protective equipment (PPE), and is therefore marked in accordance with the CE marking regulations (EN standards). Such workwear is intended to protect against accidents or injuries when working under conditions involving cold, heat, flame, rain and reduced visibility.

EU directives classify PPE in three categories:

Category 1 covers the lowest level of PPE. The user is assumed to assess the needs for protection himself, and there is a limited risk of severe consequences of not using appropriate clothing. The products under this category are self declared by the marketer to comply with the standards. HH products under this category are waterproof clothing (EN 343) and clothing protecting against cold (EN 342).

Category 2 covers products intended to be used in environments with risk for severe, but not fatal consequences (not category 1 or 3). The products must be tested and certified by a notified body. Products under this category are flame retardant clothing (EN 531/533, EN 470), clothing with protection against static electricity (EN 1149), high visibility (EN 471), lifejackets (EN 395, 396 and 399) and buoyancy aids (EN 393).

Category 3 covers products and environments where the user can be exposed to mortal danger or to dangers that may seriously and irreversibly harm health. Products under this category comply with CLC/TS 50354; clothing for use by workers at risk from exposure to an electrical arc.

Product Performance

The CE mark provides documentation that the product complies with performance standards set for a product of such nature. It is not an assurance that the product will prevent risk of accidents or severe injuries when the user is exposed to such risks in a working environment. Below is a condensed presentation of relevant EN standards

EN340

Size Designation

LCC Clothing Ireland protective clothing is designed and manufactured not to adversely affect the health or hygiene of the user. The design ensures correct positioning and cover of the body when worn correctly.

Design and fabrics provide functionality and user comfort.

The fabrics offer good colour fastness, dimensional stability, strength and durability, to assure the garments prolonged lifetime through hard wear and a high number of cleaning cycles.

The size designation is based on body dimensions measured in centimetres, ref. size chart.

The garments are marked properly on labels and hang tags to provide information as required by this standard.

(EN/ISO 11611 cancels and replaces EN 470-1:1995 and EN 470-1:1995/A1:1998)

Protective clothing during welding or similar operations

The clothing is intended to protect the user against small splashes of molten metal (EN348), short contact time with flame (EN532), and ultra violet radiation, and to be worn continuously for up to 8 hours at ambient temperature.

| This standard specifies the requirements for clothing worn during welding operations. This clothing can be worn at normal temperatures for an entire working day (8 hours) and it provides protection against small spatters of molten metal, incidental flame contact and UV radiation. This particular standard does not cover protective clothing worn for special types of welding. The contents of this standard This standard consists of a series of tests, the most important of which are described in ISO 6942, ISO 9150, ISO 15025 and EN 1149-2. ISO 11611 has two classes. If the fabric passes all the tests, it is designated as Class 1. If the fabric receives a Class-2 rating for the ISO 6942 and ISO 9150 tests, it is designated as Class 2.Different tests ISO 6942 This is a test method for assessing fabrics and fabric combinations exposed to radiant heat. In this test, a fabric sample is exposed to radiant heat (infrared rays). The temperature on the reverse (unexposed) side of the sample is registered using a calorimeter. Subsequently, the length of time the sample the sample can remain exposed before its temperature rises by 24 0C is measured. This test is also used for EN 531C and has two different classes: Class 1 temperature increase occurs after ≥ 7 seconds Class 2 temperature increase occurs after ≥ 16 seconds. ISO 9150 ISO 15025 The requirements set in this standard

Changes compared to EN 470-1:1995/A1:1998

|

||

| Criteria for choice on the basis of the type of process | Criteria for choice on the basis of the type of work | |

| CLASS 1 | CLASS 1 | |

| Manual welding operations during which small amounts of spatter or droplets of molten metal are formed – Gas welding – TIG welding – MIG welding – Micro plasma welding – Soldering brass – Spot welding – Shielded electrode MMA welding |

Operating machines, e.g. – Oxygen cutting machines – Plasma cutting machines – Resistance pressure welding machines – Thermal spraying – Welding tables |

|

| CLASS 2 | CLASS 2 | |

| Manual welding operations during which large amounts of spatter or droplets of molten metal are formed, e.g.: – MMA welding (using alkaline or cellulose electrodes) – MAG welding (with CO2 or mixed gasses) – MIG (high-voltage) welding – Flux-cored arc welding – Plasma cutting – Gouging – Oxygen cutting – Thermal spraying |

Operating machines, e.g.: – In enclosed spaces – When welding/cutting operations require reaching above head height or take place in comparable difficult positions |

|

ISO 11611 cancels and replaces EN 470-1:1995 and EN 470-1:1995/A1:1998, which have been technically revised to:

EN20471

High visibility clothing

The standard specifies requirements for clothing intended to provide visibility of the user in hazardous situations under any light conditions by day and under illumination by vehicle headlights in the dark (24 hours visibility). Effective visibility is to be provided by a fluorescent fabric and reflective stripes. The visibility is measured as a combination of the area and positioning of the reflective materials (X) and the quality of same (Y).

Related products with the EN471 Standards

EN11612

Protection against heat and flame

The standard specifies the performance requirements for protective clothing for workers exposed to heat. Limited flame spread (A) (Pass/Fail) is tested in accordance with a test method defined by EN 532. To pass the EN 531 requirements the clothing must also protect against at least one form of heat. The heat may be in the form of convective heat B (level B1-B5) according to EN 367, radiant heat C (level C1-C4) according to EN 366, molten aluminum splash (D) according to EN 373, molten iron splash (E) according to EN 373. HH products subjected to EN 531 are tested on radiant- and convective heat.

Protection against heat and flame. The standard specifies the performance requirements for the limited flame spread properties of materials and material assemblies used in protective clothing. The material(s) is classified in accordance with an index for limitation of flame spread (X) before and after a standard washing procedure (Y).

If the index is 1 (lowest level) The garment can only be used outside a garment with index 2 or 3.

EN1149

Electrostatic properties

EN 1149 constitutes a set of requirements and test methods to measure protection against static electricity or charge decay.

EN 1149-1 specifies electrostatic requirements and test methods for electrostatic dissipative protective clothing to avoid incendiary charges. This standard is used for measuring surface resistivity of woven or kitted fabrics with metal fibres providing grounding

.

EN 1149-2 specifies a test method for measuring the electrical vertical resistance of protective clothing materials. This European standard is not applicable for specifying protection against main voltages. This is a test method for measuring the electrical resistance of a fabric sample and determining whether an electrical charge passes through the sample from the outside to the inside.

EN 1149-3 specifies methods for measuring the dissipation of electrostatic charge from the surface of materials for garments. This standard is used for surface conducting or core conducting fibres, i.e. fibres without grounding.

EN 1149-5 specifies product standard requirements for electrostatic dissipative protective clothing, used as part of a total earthed system to avoid flammable discharges. The material shall meet requirements according to EN 1149-3 or -1

CLC/TS 50354

Electrical Arc Protection

This standard specifies test and classifications for materials and clothing for wearing when at risk of exposure to an electrical arc. Such clothing shall not aggravate the electrical arc consequences, by catching fire or by melting onto the skin.

The protection provided by the clothing is classified as

Specific dangers from accidental electrical arc arise from the high temperature, the pressure surge and the evaporation and splatter of hot molten metal, the effect of heat flux, noise, UV emission, hot oil or the consequences of physical and mental shock.

IEC/EN 61482-1-2:2007

Protective clothing against the thermal hazards of an electric arc – Part 1: Test methods – Method 2 – Determination of the arc protection class of material and clothing by using a constrained and directed arc (box test).

The test is intended to simulate an accidental exposure to an electric are in a low voltage installation. This standard specifies testing of materials and of complete garments on a mannequin. Material tests are used to determine thermal insulation and corresponding risks of skin burns, whereas the garment tests are to make sure that the clothing still is operational after exposure.

Both material and garment tests are carried out with a low voltage installation (400 VAC). The duration of the electric arc is 500 ms and the electric current is respectively 4 kA for class 1 and 7 kA for class 2 protection.

EN 13034-6:2005 – Protection against liquid chemicals

This European standard specifies the requirements minimal for the combinations of chemical protection of limited use and reusable (type 6). It also specifies the minimal requirements for the connections between the various parts of clothing by the use of a fog test reduced for the complete combination which constitutes a variation of standard EN468:1994. Both principal test of the pr13034 are the tests to standards EN368 (fabric) and standard EN468 (clothing). Standard EN368 sufficient step to certify this clothing. This clothing offers a limited protection against the exposure to the liquid aerosols, the fog and the light splashes where the type of potential exposure, fog, mist… is defined.